Related Blogs

How Does Low-frequency Transformer Factory Thinking Shape Power Stability?

4 minutes, 31 seconds

-13 Views 0 Comments 0 Likes 0 Reviews

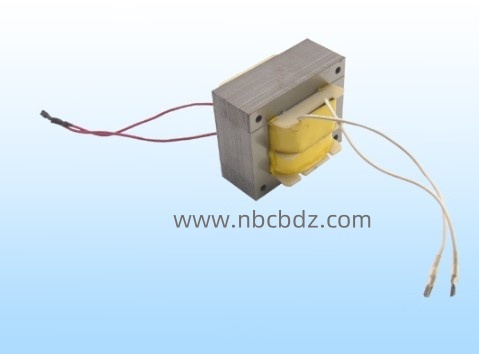

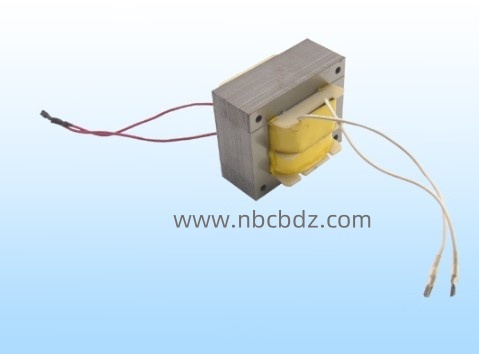

In many electrical systems, reliability grows from steady design rather than rapid change. Within this context, Low-frequency Transformer Factory operations paired with the brand philosophy of Nbcbdz reflect a manufacturing mindset centered on consistency, adaptability, and long-term application relevance. This combination highlights how established production logic continues to support modern electrical needs without relying on exaggerated claims.

Low-frequency transformers are commonly associated with dependable power conversion for equipment that values stability over compactness. Their structure allows them to handle continuous operation while maintaining predictable electrical behavior. Instead of responding to fleeting trends, these transformers are often selected for projects where durability, compatibility, and straightforward integration are priorities.

The manufacturing process behind such transformers emphasizes disciplined workflows. Core assembly, coil winding, and insulation placement are handled with attention to uniformity, ensuring that each unit aligns with intended design parameters. This approach helps reduce variation between components and supports smoother installation across different systems. For engineers, this consistency simplifies planning and reduces the need for compensating adjustments elsewhere in the design.

Another important aspect lies in material coordination. Low-frequency transformers rely on carefully matched cores and windings to manage magnetic flux efficiently. Thoughtful material handling supports stable operation under varying load conditions, which is especially valuable in industrial and infrastructure-related applications. The goal is not to push limits, but to maintain balance throughout prolonged use.

Customization also plays a meaningful role. While the operating principles may be well established, application requirements are rarely identical. Transformers may need to adapt to specific mounting methods, enclosure constraints, or interface expectations. A flexible production structure allows these adjustments to be addressed during manufacturing rather than after deployment, helping projects move forward with fewer interruptions.

Thermal management is another area shaped by manufacturing decisions. Low-frequency designs often involve larger physical structures, making heat dissipation an important consideration. Proper spacing, insulation choices, and assembly techniques contribute to steady thermal behavior. When managed thoughtfully, these factors help extend component usability and support reliable operation over time.

Sustainability considerations increasingly influence production philosophy. Responsible material usage, organized workflows, and attention to service life all contribute to reducing unnecessary replacement and waste. While these efforts may not be visible during operation, they shape the broader lifecycle of equipment and support more responsible system planning.

Equally significant is communication between production teams and system designers. Clear discussion of operating environments, load expectations, and installation conditions allows transformers to be produced with practical context in mind. This exchange supports alignment between design intent and real-world use, strengthening overall system coherence.

As technology continues to advance, low-frequency transformers remain relevant because of their dependable nature. They serve as foundational components in systems where steady power delivery matters more than rapid miniaturization. Their continued use demonstrates that progress in engineering often includes refining established methods rather than replacing them entirely.

Understanding how these transformers are produced offers insight into the broader values of electrical manufacturing. Careful processes, adaptable thinking, and respect for application realities all contribute to components that quietly support complex systems day after day.

If this perspective has sparked new ideas about power design and manufacturing balance, a deeper conversation is only a click away. Step into more insights and possibilities by visiting https://www.nbcbdz.com/ and see where thoughtful engineering can lead.

Photos