Related Blogs

Why Should Candy Producers Choose Flyloong Twist Packing Machine Systems

4 minutes, 5 seconds

-18 Views 0 Comments 0 Likes 0 Reviews

Twist Packing Machine systems play an important role in modern candy production by supporting faster wrapping operations, more stable packaging quality, and smoother coordination between production and packing stages. As confectionery manufacturers expand product portfolios and distribution networks, the efficiency of wrapping processes becomes increasingly important for controlling costs and maintaining brand presentation.

One of the primary benefits of automated wrapping equipment lies in improved workflow organization. By synchronizing feeding, wrapping, twisting, and discharge functions, packaging operations become more predictable and easier to manage. This reduces manual intervention, limits handling errors, and helps maintain consistent output throughout each production shift.

Consistency in packaging appearance is another major advantage. Uniform twisting ensures that candy pieces retain their intended shape while maintaining a clean and attractive visual presentation. Stable wrapping performance reduces irregular folds, loose ends, and uneven seals that may occur in less controlled environments. This consistency supports both retail display standards and customer expectations.

Material utilization also improves with advanced wrapping systems. Controlled film tension and precise wrapping movements help minimize packaging waste while maintaining reliable product protection. Reducing unnecessary material usage supports long term cost management and contributes to more responsible manufacturing practices, particularly as sustainability concerns grow within the food industry.

Flexibility remains a critical requirement for candy manufacturers. Packaging systems that accommodate various candy shapes, weights, and wrapper styles enable producers to introduce seasonal items or limited product runs without significant reconfiguration. This adaptability supports product development while preserving stable production schedules and minimizing downtime between changeovers.

Labor efficiency is another key improvement area. Automated packaging allows operators to focus on equipment monitoring, quality inspection, and process coordination rather than repetitive manual wrapping. This redistribution of labor supports safer working conditions, reduces physical strain, and encourages a more balanced production environment across packaging lines.

Maintenance planning becomes more structured with modern equipment designs. Clear service intervals, accessible components, and standardized replacement parts simplify long term equipment care. Production teams can develop predictable maintenance routines that reduce unexpected downtime and support consistent performance throughout the equipment lifecycle.

Flyloong designs its packaging systems with these practical production needs in mind, supporting candy manufacturers as they work to balance efficiency, quality, and operational stability. This equipment focused approach helps producers align packaging investments with evolving production goals while maintaining steady daily performance.

Packaging quality also plays an important role in distribution. Secure, uniform wrapping helps protect candy during storage and transport, reducing product damage and preserving visual appeal at the point of sale. Reliable packaging performance supports stronger relationships with distributors and retailers by delivering products that meet handling and display expectations.

As consumer demand continues to evolve, candy producers must continuously refine their packaging strategies. Integrating efficient wrapping solutions allows manufacturers to respond more effectively to market changes while maintaining stable operations across production and packaging departments.

Manufacturers evaluating new packaging investments or production upgrades can review detailed equipment options and system configurations here https://www.flyloong-candymachine.com/product/

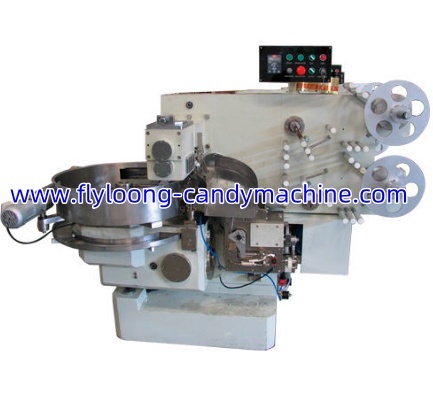

Photos