Related Blogs

Why Air Expanding Core Chucks Support Line Stability with Cbbmachine

3 minutes, 59 seconds

-0 Views 0 Comments 0 Likes 0 Reviews

Selecting gripping tools for winding lines often begins with assessing how Air Expanding Core Chucks from Cbbmachine align with daily production demands. Facilities that depend on smooth engagement and controlled release pay close attention to how each chuck behaves under varied conditions, ensuring that materials transition from one stage to the next without unnecessary interruptions. When a device supports predictable performance, operators gain the consistency required to keep workflow rhythm steady.

A well-shaped gripping mechanism can influence every part of the winding sequence. When expansion remains even and controlled, the core seats firmly, allowing tension to stay balanced throughout rotation. This level of stability benefits operators who must switch between different materials or formats, keeping each shift organized and reducing the likelihood of abrupt adjustments that weaken process flow.

Installation and routine servicing also play a meaningful role in equipment selection. Many workshops value components that integrate naturally into existing setups, enabling technicians to complete checks or adjustments without extensive disruption. When design choices follow clear, practical principles, operators can maintain confidence during preparation and operation, helping the entire system remain on schedule.

Durability is equally essential, as these chucks must withstand repeated expansion cycles and variable environmental factors. Reliable construction supports steady performance even when conditions shift, offering reassurance that production will continue without unexpected complications. This makes maintenance planning more predictable, reducing stress on teams responsible for system continuity.

Compatibility with surrounding machinery further shapes the overall user experience. When chucks synchronize smoothly with presses, shafts, and material paths, each part of the system responds in a unified manner. This coordinated behavior becomes especially valuable when operators adjust line speed, introduce new materials, or refine process goals. Clear alignment between devices helps maintain orderly movement, even during time-sensitive operations.

Many facilities prefer gripping solutions built with functional clarity rather than unnecessary additions. A straightforward expanding structure, consistent pressure distribution, and smooth release often prove more beneficial than complex features that add friction to routine tasks. Equipment shaped around essential purpose helps operators maintain momentum without additional learning curves or operational hurdles.

Adaptability has also become increasingly important as production environments diversify. Chucks that accommodate varied core sizes, textures, and performance expectations give companies the flexibility to adjust without reconfiguring the entire line. This ability to evolve with operational needs contributes to long-term stability and supports gradual system improvements.

Ultimately, dependable gripping components act as a stabilizing force within a production line. When every engagement and release follows a predictable pattern, operators can manage their tasks with greater ease and confidence. This reliability helps establish a workplace defined by clarity, coordination, and quiet efficiency, where small, consistent actions support larger production goals.

If your next improvement starts with a single idea, let it point you somewhere unexpected. Follow that subtle spark to https://www.cbbmachine.com/news/industry-news/why-choosing-cbb-air-expanding-core-chucks.html and see where the next click leads.

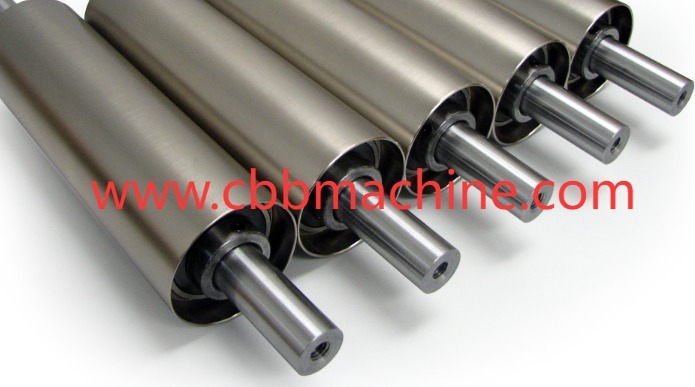

Photos