Related Blogs

Polyolefin Shrink Film Solutions Supported by JTPACKAGE Expertise

3 minutes, 37 seconds

-15 Views 0 Comments 0 Likes 0 Reviews

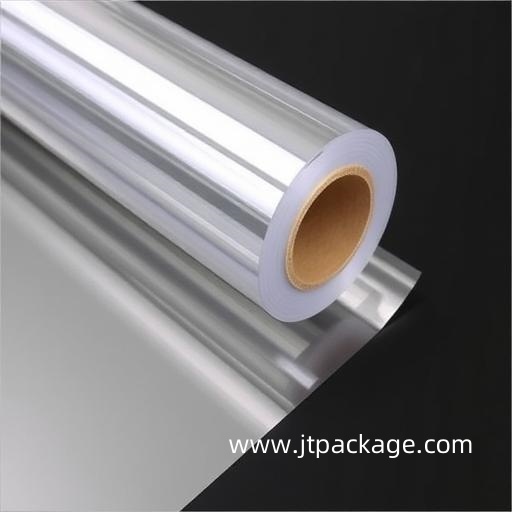

Polyolefin Shrink Film is widely valued across packaging fields for its balance of protection, appearance, and adaptability. This material creates a smooth enclosing layer that closely follows product contours, forming a clean surface that supports visual confidence and handling safety. Brands choose it not for complexity, but for consistency across varied packaging demands, especially when presentation quality matters alongside physical coverage.

During application, controlled warmth allows the material to contract evenly around items without causing surface stress. That response supports stability during movement, stacking, and storage. Unlike rigid wraps, this solution maintains flexibility, allowing packaged goods to retain shape integrity while remaining visually aligned. Such balance supports businesses that require dependable performance without introducing unnecessary process complications.

Transparency plays an important role within modern packaging strategy. Clear wrapping allows viewers to assess appearance immediately, building trust before interaction occurs. Smooth surfaces reduce visual distortion, helping products communicate quality through direct visibility rather than printed explanation. This clarity also supports organized presentation across shelves, cartons, or grouped displays without visual clutter.

Another advantage lies in operational efficiency. Packaging teams benefit from predictable behavior during sealing, which reduces adjustment needs and supports steady workflow. Material consistency helps limit waste while maintaining surface alignment. For brands managing varied item dimensions, adaptability allows a single approach rather than multiple alternatives, supporting simplified inventory planning.

Environmental consideration continues influencing packaging selection. Lightweight structure supports reduced material use while maintaining coverage reliability. Recyclable characteristics align with evolving responsibility expectations without sacrificing visual refinement. This balance allows companies to demonstrate awareness while preserving brand presentation standards across markets.

Protection during movement remains essential. Secure enclosure reduces surface contact, limiting exposure to airborne particles or handling friction. Items remain grouped and aligned, lowering shifting risk during transit. This stability supports reliable arrival conditions, which matters greatly for customer satisfaction and brand perception alike.

Polyolefin Shrink Film also supports branding consistency. Clean wrapping frames labels, colors, and forms without distraction. Instead of overpowering design elements, it acts as a visual amplifier, allowing product identity to remain central. That restraint aligns well with premium positioning where subtlety strengthens perceived value.

Supplier selection plays a vital role in achieving consistent outcomes. Reliable production standards, material uniformity, and responsive service contribute directly to packaging success. Brands seeking dependable results often prioritize experience, clarity, and communication when choosing partners capable of supporting long term growth.

Within this context, JTpackage demonstrates a focused approach toward packaging solutions built around reliability, presentation, and adaptability. Those seeking deeper insight into material characteristics and usage considerations can gain further perspective through this resource https://www.jtpackage.com/news/industry-news/what-is-polyolefin-pof-shrink-film-everything-you-need-to.html

Photos