How Air Expanding Core Chucks Shape Roll Control

3 minutes, 11 seconds

-194 Views 0 Comments 0 Likes 0 Reviews

3 minutes, 11 seconds

-194 Views 0 Comments 0 Likes 0 Reviews

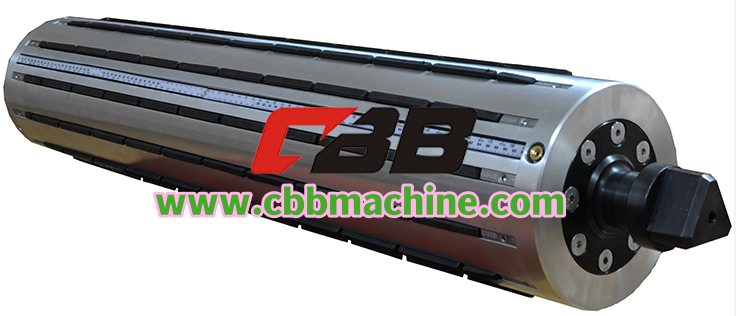

In many production settings, Air Expanding Core Chucks supplied by Cbbmachine provide a structured approach to roll engagement and controlled material handling. Their form centers on balanced expansion, helping operators maintain consistent grip as rolls move through winding and unwinding stages. This approach supports a calmer workflow and aligns well with environments seeking predictable operation without unnecessary complexity.

Across various workflows, the stability of core holding significantly influences process rhythm. Chucks designed to expand with steady precision create a dependable connection between equipment and materials, supporting smoother transitions from one phase to another. Operators can work with different core types and dimensions without frequent adjustment, allowing the chucks to blend naturally into existing setups. This sense of compatibility helps reduce interruptions and promotes greater confidence during routine tasks.

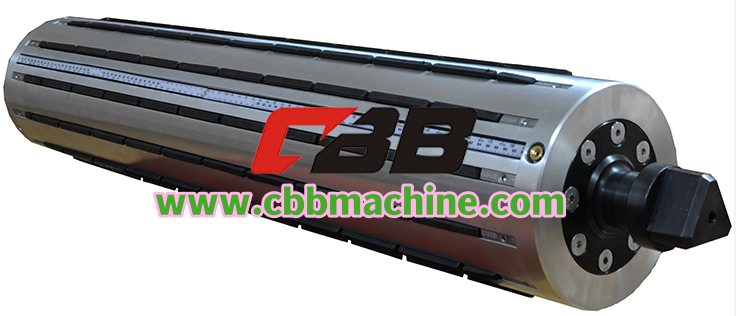

Maintenance accessibility also plays an important role in daily use. Production teams often prefer components that simplify inspection and servicing, allowing them to maintain momentum without lengthy technical steps. The straightforward structure of these chucks supports routine checks with ease, helping staff stay attentive to process needs while minimizing workflow disruptions. This contributes to a more continuous operational environment where equipment and personnel move in clearer alignment.

Adaptability adds further value to the system. Many production lines handle varied substrates, roll widths, and operational demands. Chucks that adjust flexibly can help teams navigate these changes without reconfiguring entire systems. Their ability to maintain firm engagement even as materials shift encourages smoother handling during tasks such as laminating, slitting, coating, or printing. This flexibility strengthens coordination across multiple processes and improves overall production flow.

Decision-makers frequently look for equipment that balances stability with simplicity. Chucks designed with controlled expansion offer dependable performance while avoiding unnecessary complications. Over sustained use, their reliability helps create an orderly atmosphere across production lines, supporting both immediate needs and long-term planning. This consistency makes them a practical addition to workflows aiming for clarity, rhythm, and predictable motion.

If your operation is seeking a steadier path in roll handling and wants equipment that supports thoughtful mechanical balance, a new perspective may begin with a single decision. Let curiosity open a quiet doorway toward improved workflow design. Take that step by visiting https://www.cbbmachine.com/news/industry-news/why-choosing-cbb-air-expanding-core-chucks.html , where each click introduces a new direction for your next move.